What are the 16 different types of slabs in construction?

Bridges, roofs, foundations and driveways all rely on durable concrete for a firm base and dependable structure. Find out how to compare the 16 common concrete slab types today before planning a construction project. Assess your concrete slab needs the right way with professional measuring devices and

construction tools from Engineer Supply.

1. One-Way Flat Slab

One of the most common slab types in construction projects, a one-way flat slab uses between 4 and 6 inches of concrete to withstand heavy loads. The name of this slab refers to the support structure. It’s designed to be used in applications where one direction is supported and the other direction requires less support.

This type of slab is an affordable, simple solution for commercial or residential projects. It’s more affordable than other types of slabs, particularly for a ground-level structure. A major limitation to one-way flat slabs is that they don’t have the same span capabilities as other slab types. This makes them unsuitable for many bridge and ceiling applications.

2. Two-Way Flat Slab

A two-way construction uses support beams at all four corners to equally distribute weight throughout the entire slab. This type is commonly used in a multi-storeyed building, where floors need to support the weight of additional floors. The best way to determine which type you need is to review the breadth and width of a particular project. If one direction is longer than the other by a ratio of two to one, then you should consider a one-way slab.

3. Kitchen Slab

This particular slab type is used in residential construction projects for a kitchen platform. It’s commonly used to place a stove on a fire-resistant surface. The small design of this slab isn’t suited for structural purposes, but can be used to support an oven or other cooking appliance.

4. Sun Shade Slab

A sloped slab of concrete above a door or window is called a sun shade slab. This specialized structural piece is used to shade the door or window from direct sunlight and pouring rain. It’s typically poured separately and installed on the exterior of a building after fully curing. Use a sun shade slab as a sturdy alternative to a steel or fabric sun shade.

Sun shade slabs don’t need to be particularly thick, as they aren’t traditionally structural elements. Instead, they must simply be thick enough to support their own weight safely. Be sure you review the materials used to safely secure the slab above a window or door to prevent a falling hazard.

5. Lintel

Windows and doors are structural weak points in a wall. Because these features don’t provide the same load-bearing functionality as bricks, concrete or timber framing, your building may require a lintel. This structural piece is placed above a window or door and redirects the top load.

A precast lintel is a popular option for generic dimensions and materials. These lintels are constructed in a factory, so they are typically more affordable and convenient than in situ lintels.

Lintels that are cast in situ are cast and poured at the jobsite. Instead of constructing them in a factory, the concrete is mixed, framed and poured either directly above the window or door or poured at the jobsite. This allows for a special concrete mixture or design for your building project.

6. Sunken Slab

Residential and commercial jobsites may require a sunken slab in washrooms or around other fixtures. These construction situations require a slab that is below the floor grade and accommodates water and sewer lines. A sunken slab typically has a slope and is below grade enough to fit a shower base or other fixture so that the top of the fixture is flush or closer to flush with the floor. Use a

construction level to determine the recess needed to accommodate both the slab and the fixture.

7. Cable Suspension Slab

Bridges are the most common area where cable suspension slabs are used. Stretch long spans without compromising the structural integrity of the concrete surface. This type of slab can also be used in commercial construction to create a floating foundation or raised walkway between buildings.

The size and frequency of suspension cables depends on many critical factors. You’ll need to calculate the weight of the slab, the length it’s being suspended and the expected load. These factors help you arrive at optimal slab dimensions and suspension considerations before you design the columns to support the bridge or other structure.

8. Pre-Tension Slab

Lay tightened steel cables as a reinforcing skeleton of your concrete slab. Similar to a post-tension slab, a pre-tension slab is used to prevent compression and improve overall strength. It achieves this through the use of high-tensile steel cables. Hydraulic jacks create tension in the system before the concrete is poured into the framework. If the structure should crack, the tension of the cables prevents the concrete pieces from dangerously separating.

Use a pre-tension slab for a thinner product. Compared to other reinforced slabs, pre- and post-tension slabs don’t require as thick of concrete. The tension in the slab also reduces the need for joints. In some structures, the slab will be entirely joint free.

9. Waffle Slab

Looking remarkably like a waffle, this finished slab creates an iconic look that’s commonly used in restaurant, mall and other commercial settings. A grand lobby can use this square-pod system to house recessed lights, alter acoustics and create a wide span with minimal column support.

The construction and installation of a waffle slab is particularly costly and time consuming. While the result is a stunning structure and memorable interior, the process can be too costly for many commercial or residential projects.

10. Pitched Roof Slab

Mimic the look of a shingled or steel roof with a pitched roof slab. This sloping design typically uses thin tiles that are lightweight and easy to install. This roofing material typically needs steel or timber framing to support it. It isn’t suitable for large spans without support, but it can be a great investment that reduces the maintenance of a particular building. Use

construction tools to calculate the ideal pitch for your area to avoid overloading it with snow or other weight limit factors.

11. Post-Tension Slab

The post-tension slab offers the same characteristics of the pre-tension slab. Instead of tightening the cables and creating tension before the concrete is poured, this process occurs afterward. It offers a similar lightweight, durable result. Use care when choosing this option, as an inexperienced concrete team may leave air pockets in the slab. These pockets encourage steel cable corrosion and increase the risk of a sudden slab failure.

12. Hollow Core Slab

These convenient slabs are pre-poured and delivered to your jobsite. This reduces the amount of labor and time needed for your project. Simply use a crane to lift and install the hollow core slabs on supporting columns.

Compared to other slab options, hollow core slabs offer an excellent span distance. They also have holes through them that are perfect for installing wiring and plumbing, which further reduces the time and cost of the construction project.

Be sure you order hollow core slabs from a reputable contracting team. Casting errors and improper transportation can damage these slabs, which quickly turns into a costly and time-consuming situation.

13. Hardy Slab

Concrete blocks are placed together to create a slab in a technique known as hard slab. Once these blocks are stacked in place, a formwork is arranged around it and reinforcement is placed in between blocks. Concrete is then poured around the blocks.

This technique is most often used in hot climates. It not only saves on concrete costs, but also enjoys greater heat and sound insulation than other slab types. It doesn’t have the same load limit as other slab types, and can be more costly to repair, but it’s a convenient and economic option for mid-to-long spans and moderate loads.

14. Dome Slab

An iconic mosque, temple or palace dome can be constructed using a dome slab. This semi-circle concrete structure uses a steel support structure. The concrete is moderately thick and is carefully poured using a framework to achieve a smooth or textured dome shape.

15. Projected Slab

A covered drop-off entrance usually includes a projected slab. This long slab is connected to a building at one end and hangs free at the other. The goal is to protect vehicles and pedestrians from direct sunlight and inclement weather. The slab uses a cantilever design to balance the weight and safely support it from a single end.

16. Room Chajja

Open up ceiling space for additional storage with a room chajja. This slab can be used as a built-in shelf inside your home. It’s not meant to provide a structural element or a load-bearing loft, but can be a stylish built-in shelf in your kitchen or dining room.

Frequently Asked Questions

How Many Types of Concrete Slabs Are There?

There are 16 different types of concrete slabs used in construction projects. Flat slabs are some of the most common types used in commercial construction projects. Consider a flat slab for a parking lot or a floor with or without drop columns. Other options are ideal for specialized projects, such as kitchen slabs.

How Can I Compare Slab Options?

Consider the type of construction project and structural considerations before selecting the right slab type. Every slab option offers different pros and cons depending on your process. Review the weight considerations, available budget and support structures before selecting the best slab. Engineering calculation tools are critical to evaluating the dimensions and support structure.

How Is a Slab Constructed?

The process starts with formwork and a foundation of smooth earth or gravel. Once the frame is installed, the concrete must be mixed and poured into place. Finishing the concrete creates a smooth, consistent surface before it can cure. Depending on the thickness of the slab and mixture being used, it can take up to 60 days to fully cure.

How Do I Accurately Measure a Slab?

Use a construction laser level and other professional tools to measure out the slab. Spend the time to carefully mark out your intended slab location to prevent dimensional issues. A slab that is sloping or irregularly shaped could compromise the entire building project and require costly alterations.

What Are the Dangers of Choosing the Wrong Type of Slab?

Every type of slab has its own structural considerations. Choosing the wrong type of slab could cause it to crack under the strain of its own weight, the building constructed on it or regular traffic flow. This situation is costly and could be dangerous to anyone in the building or driving on the concrete surface.

Shop for tools today at Engineer Supply to prepare the way for a smooth, level and square concrete slab. Use

construction tools and calculators to accurately estimate the scope of the project before working with contractors to complete your commercial or residential project.

Construction Safety Vests

Construction Related Articles

Best Construction Level

This 26x transit level has an accuracy of 3/16 of an inch at distances of up to 150 feet, but it has a total range of 400 feet. The optics have a horizontal circle with a lock and tangent as well as a vertical arc with a lock and tangent. It also has a 5/8" x 11" thread size and a 1:100 stadia with a glass reticle. When you purchase this construction level, you will also get the following:

- Optical plummet

- Rain hood

- Objective lens cap

- Hard carrying case

If you’re ready to purchase this level, be sure to pick yours up at Engineer Supply.

This automatic level will allow surveyors and construction professionals to get accurate level, angle, height and distance measurements. The optics have a 32x magnification, a 1/32-inch accuracy, and a built-in compensator that will stabilize the line of sight (even in the presence of fine vibrations that can be caused by heavy equipment on the job site).

The telescope has a focus range of 7.9 inches and can be used in confined spaces. It also has an internal magnetic dampened compensator, which will allow you to level the line of sight within a range of 15 arc minutes at an accuracy of 0.3 arc seconds. You can even get it with the following accessories:

- Diagonal eyepiece.

- Optical micrometer.

- Light pack (which can be helpful low-light conditions).

- 40x eyepiece (which will improve accuracy and magnification).

Be sure to pick yours up at Engineer Supply today!

This construction level has been proven to provide both precision and durability. It also features enhanced reliability in all types of environmental conditions. Its tough and compact body has an IPx6 Rating. So, it will be resistant to damage caused by water, humidity, and dust. It also has a number of useful features, which can include but may not be limited to:

- Precise and reliable automatic compensator — It has four high-tensile suspension wires and a magnetic dampening system, which will ensure accuracy and stability (even when it’s exposed to temperature changes, vibrations, or shock).

- Superior telescope — It can provide an exceptionally bright and sharp view that will minimize eye strain. It also has an ultra-short focus of 7.9 inches (20 cm) from the end of the telescope, which makes it easier to use in confined spaces.

- Quick collimation — The two knobs of endless horizontal motion drives can be operated with either hand, which allows for faster and easier aiming.

- Horizontal angle measurement — Horizontal angles can be read in one-degree or one-gradian units, and the freely rotatable circle will allow you to perform any angle reading from zero.

The stadia lines on the reticle will allow you to perform any distance measurement, and it’s easy to adjust with one screw. The circular level vials are adjusted with two screws, but both of them are quick and easy with the provided tools.

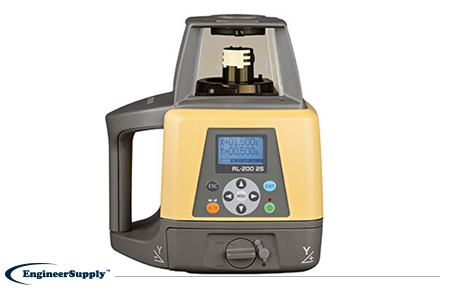

This self-leveling, dual-slope rotary construction laser level is great for exterior applications and it includes the following:

- Rechargeable battery kit.

- LS-100D laser detector with the Holder 6 rod clamp.

- RC-400 remote control.

- Hard carrying case.

The red laser beam has an operating range of 3,600 feet in diameter with a laser detector, and it has an accuracy of 3/64 of an inch at distances of up to 100 feet.

This construction laser level has an operation range of up to 800 meters, and it comes with a smart long-range receiver. The laser has a rotation speed of 600 rpm with a self-leveling range of five degrees. The battery can last up to 100 hours, and the body has an IP66 Rating (which allows it to withstand dust, a sudden shower, or even heavy rainfall). When you purchase this laser level for construction, it will come with a 5-year manufacturer’s warranty as well as the following accessories:

- Topcon LS-80L Laser Detector.

- Sensor holder.

- Carry case.

Be sure to pick yours up at

Engineer Supply today!

Please Wait...